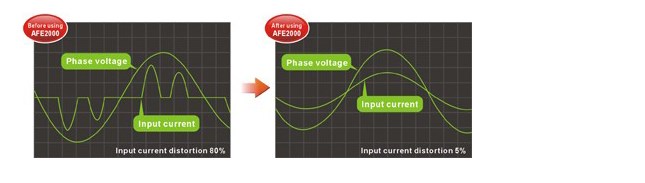

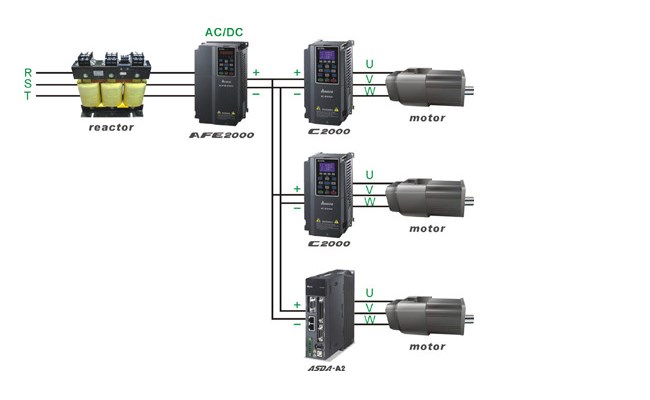

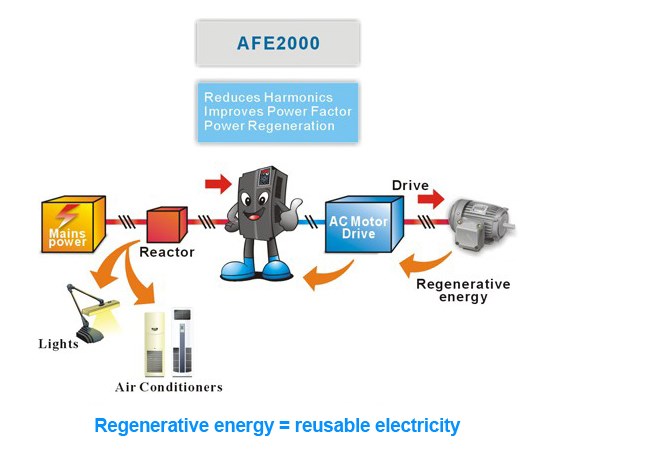

Active Front End (AFE) is a controllable rectifier with advantages such as providing bidirectional power exchange between AC and DC power and regenerating reusable power to the mains to reduce the cost of power. The AFE uses PWM modulation to greatly reduce distinctive peaks of current and form perfect sine wave current. The power factor is corrected up to 1—the ratio between load capacity and power capacity is 1:1.In addition, the AFE eliminates high order harmonics, provides very low harmonic current THD<5% while improving the power factor, which allows you to save the cost of purchasing additional electrical equipment for better power quality,. The AFE also offers stable power quality unaffected from mains power fluctuations and can be applied to a serial connection.

Incorporating years of experience in AC motor drive development, Delta introduces the innovative AFE2000. This unit is designed for a wide range of applications and it achieves outstanding energy saving results. The AFE2000 does not dissipate excess heat into the air but converts it into reusable power that can be supplied back to the mains. The AFE2000 is yet another Delta product that contributes to improving efficiency and productivity and that fulfills our mission “to provide innovative, clean and efficient energy solutions for a better tomorrow”.