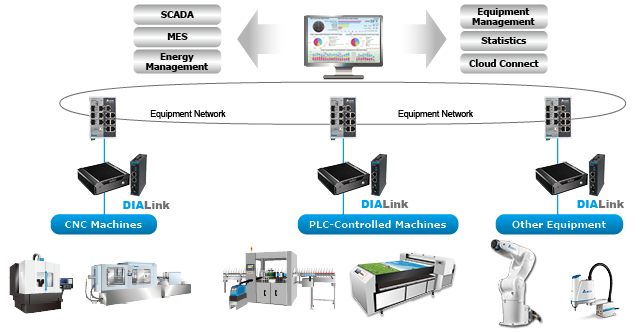

Delta Equipment IoT Platform DIALink is designed for collecting on-site equipment’s operating data from CNC machine tools and PLC-controlled equipment, providing a unified interface to the upper management systems, as well as achieving data visualization that efficiently reveals production parameters and operating status in real-time. The DIALink adopts second development functions with edge computing and IoT technology to achieve factory automation and visualization.

With the progress of smart manufacturing, industrial automation is integrating intellectual machines, manufacturing execution systems, and cloud platforms. As an application of edge computing, the DIALink can achieve higher equipment efficiency and energy-savings through data communication, analytics and logical operations.

Features & Benefits

Building IoT in a Snap

Collects equipment data and transmits to the cloud database

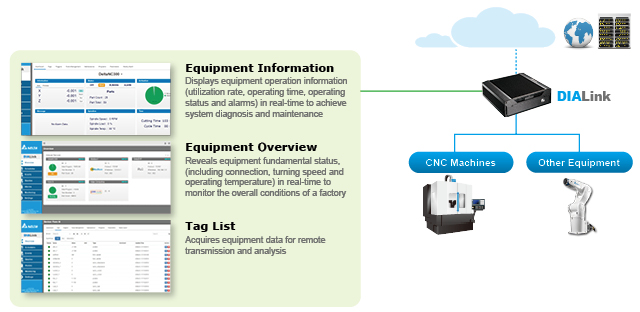

Visualized interfaces for clear and intuitive equipment information display

Web-based interfaces for easy setups and system development

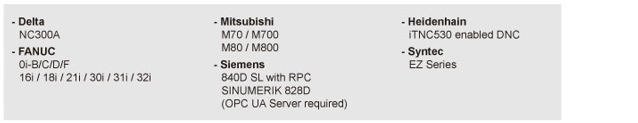

Supports third-party CNC controllers

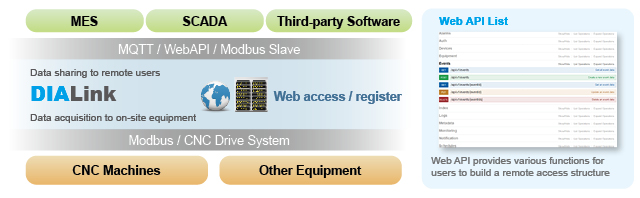

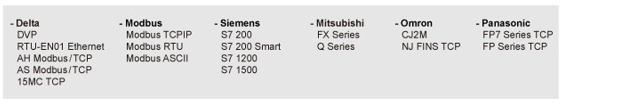

Adopts Modbus communication for equipment integration

Connects the cloud platform via MQTT / WebAPI / Modbus Slave for enhanced data access efficiency, as well as simplifying processes for remote system and third-party software integration

Edge Computing Technology

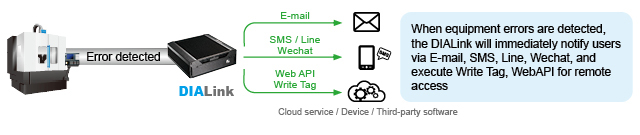

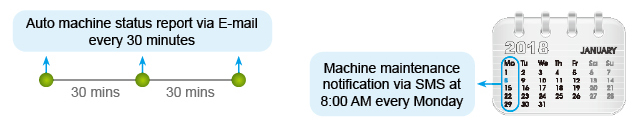

Events and Schedules

Allows the system to trigger events under specific circumstances. When an event is triggered, the system will send messages or execute Web API in real-time

Existing events can be set up to be triggered based on fixed time intervals or a specific time schedule

Real-time Monitoring, Analysis & Response

Calculates usable data for equipment data collection in real-time

Driver list

Supports third-party CNC controllers

Supports third-party PLC

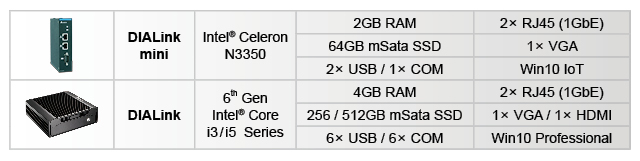

Hardware Specification

Applications

System Structure

Widely applied in various industries through integration with different industry knowledge bases