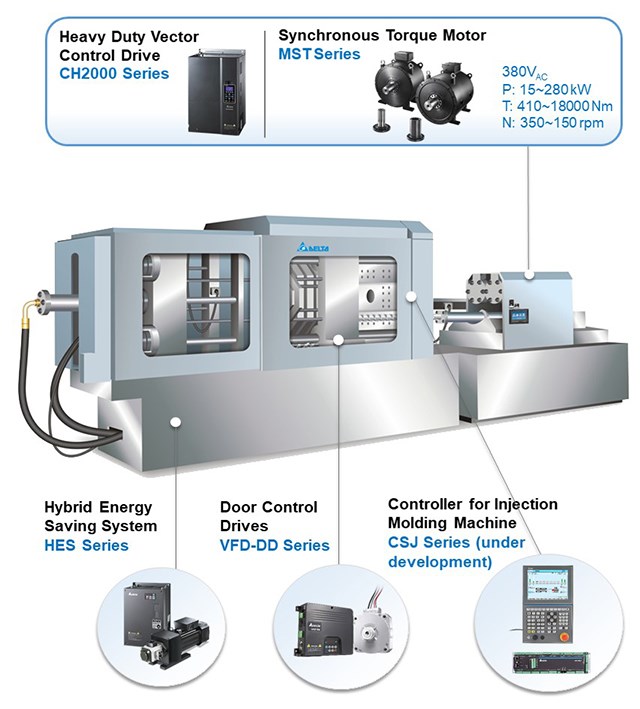

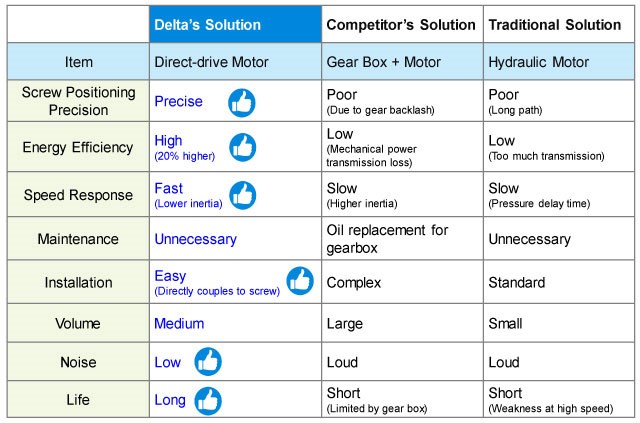

The Synchronous Torque Motor MST Series is designed for excellent performance at low speeds and is suitable for high torque applications. It implements synchronous motions with high-speed response for acceleration and deceleration to shorten processing time and achieve high productivity. Featuring a direct-drive mode and stable rotating speed, the MST series accurately controls plastic melting and the quality of plasticization, and enhances the yield rate for the fiber-reinforced injection as well. With high efficiency and high accuracy, it is applicable to miscellaneous shaft sleeves for various demands and applications.

The MST series is built with a robust structure for easy installation and maintenance and offers a longer lifespan. It is the perfect replacement for hydraulic motors or gear motors.